Introduction of TPEE:

TPEE(also called as TPC、TPC-ET、TEEE) is a block copolymer which contains a hard segment of polyester and a soft segment of polyether; wherein the amorphous is formed from the soft segment of polyether and the uncrystallized polyester. Micro-crystals play a role as physical crosslinking points formed from the hard segment of the polyester.

TPEE has the rubber elasticity and strength of engineering plastics. Soft segment gives it flexibility to make it like rubber; hard segment assigns the processing properties which makes it like plastic. Compared with rubber, it has a better processing performance and longer life; and the same high strength characteristics compared to plastic, while the flexibility and dynamic mechanical properties is better.

TPEE has high strength, high flexibility, oil resistance, high temperature, radiation, dynamic mechanical properties superior to other properties;

SUNPRENE@TPEE service temperature range :-100℃~+180℃,hardness range: 20~75D,

The available grades of SUNPRENE@ TPEE are grouped into 5 categories by performance: high-performance grade, flame retardant grade,blow molding grade, extrusion grade, and modified grade.

一、High-performance grades of SUNPRENE@TPEE

SUNPRENE@TPEE are the main product of our company. They exhibit high structural strength, good creep resistance, excellent resilience, impact resistance, bend fatigue resistance, friction resistance, and dimensional stability. In addition, SUNPRENE@TPEE has flexibility at low temperature and keep good performance at elevated temperature. They can resist many industrial chemicals, oils and solvents leading to corrosion.

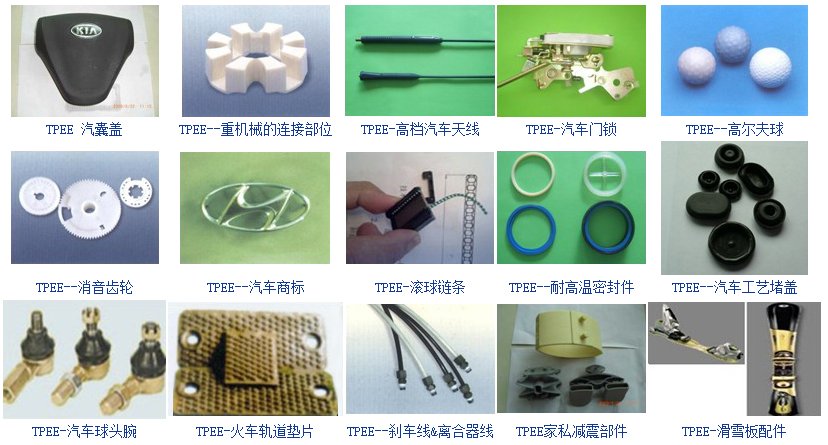

The typical application and their pictures of High-performance grades of SUNPRENE@TPEE

Automotive parts:Airbags accessories, after the suitcase lock assembly, door lock assembly, door handle seal ring, vibration plate, silencer gears, pipe closers, plugs, ball-end, windows seat shock, shock chassis, stone chip resistant coating chassis, etc.

Shoemaking: Sole, heel, roller skates or roller skates wheels, etc.

Electronics and electrical appliance:Welding the cable sheath, electrical flexible button, cordless phone antenna covers, wire and cable, etc.

Industrial manufacturing:Elevator slide, high-pressure washer, silencer gear, spring cigarette machines, instruments and so on. Electric tools, sports goods, plastic alloys, daily necessities (toothbrush handle).

二、Flame retardant grade SUNPRENE@TPEE

The series have good fire resistance, toughness and high or low temperature performance. It also retains the physical and chemical properties of the material itself,.Meet a variety of fire and flame retardant purposes, including: electronic components, cables, hoses, sheaths, etc.

ROHS reports can be provided for some grades . When the wire rod and so on toughness and fatigue resistance have higher requirements, high temperature materials can partially substitute Teflon as wire rod. The model can be used for injection molding, extrusion molding process.

三、Blow molding grades of SUNPRENE@TPEE

With excellent processing performance, high toughness, fatigue resistance, and maintain excellent mechanical properties and flexibility in high or low temperatures. In addition to the series features a high performance level, but also has good melt strength, etc.

Typical applications for parts with pictures and grades:

For the production of a variety of jacket and hose, such as: steering sheath, shock absorber jacket, dust cover, traction coupling cover, distance bellows, engine intake duct, clothing lining film, etc.

四、Extrusion grade SUNPRENE@TPEE

With excellent processing performance, high toughness, fatigue resistance, and maintain excellent mechanical properties and flexibility in high or low temperatures. In addition to the series features a high performance level, but also has good melt strength, etc.

五、Modified grades of SUNPRENE@TPEE

Used to improve the erosion resistance of POM/PBT/PET.blend with the PVC ,PS, PVC and PC to have excellent adhesion.

The guideline of process:

Before the molding process, TPEE must be dried under oven at 100-110 ℃ for 3-5h, and then processed immediately, not to let they cooled and in damp air,moisture will affect their performance.

Processing technology:

Blow molding:barrel temperature should be higher than the melting point of products 5~15 ℃, mold temperature at 40-70℃.

Extrusion of wire rod: when extruding wire rod and other parts, the barrel temperature should be 5-10℃ higher than the melting point of the product, the recommended length-diameter ratio is 24: 1, and the screw speed is medium and low.